M12防水圆形连接器的螺丝扭矩控制方法:螺纹连接及其影响因子进行分析。188bet官网1结合生产实践,当四轴前轴和后轴U型螺栓拧紧机的输出扭矩达到目标值(扭矩值在主监视操作显示屏上显示),螺母的扭矩无法满足过程规范的要求测试和分析动态扭矩和静态扭矩之间的差异。扭矩控制值是通过统计方法获得的。在扭矩控制过程中引入了动态扭矩和静态扭矩的概念,以建立扭矩控制方法,该方法应用于产品质量控制过程。

螺纹连接通过螺栓轴向拧紧力连接两个部分,这是机械产品中的常见连接模式。螺栓轴向拧紧力对连接强度,螺纹对抗松动和连接部件之间的密封有直接影响。稳定且适当的轴向预紧力是可靠连接的前提。在实际工作中,直接测量螺栓轴向夹紧力并不方便,因此通常有必要控制螺栓扭矩以获得适当的轴向夹紧力。

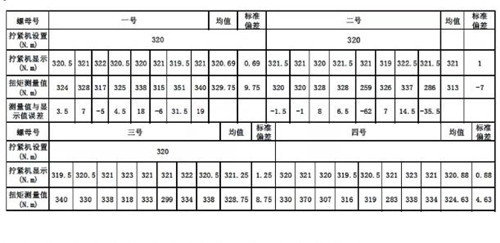

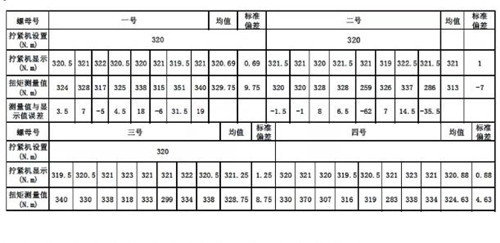

在工程车辆的前后桥和叶弹簧的组装过程中,在确认连接零件,线对和操作方法的条件下,进行了骑行螺栓和螺母的预拧紧,进行了稳定的条件。状态,电拧紧机用于拧紧要测量的螺母,然后通过数字显示扭矩扳手检测到扭矩值。发现扭矩值不一致,无法满足过程规范的要求(如表1所示)。本文分析了问题,并提出了解决问题的方法。

前提:1。过程指定的扭矩:200N。M ~250N。m;2.设置拧紧机器的扭矩:250N。m

1,分析影响扭矩的因素

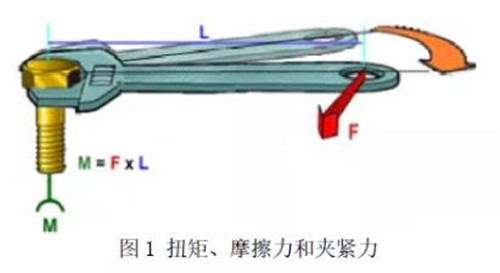

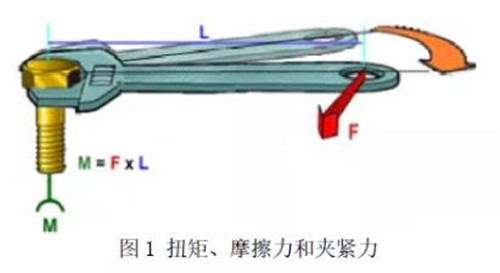

扭矩,摩擦力和夹紧力之间的关系如图1:扭矩(M)=力(F)×ARM(L)

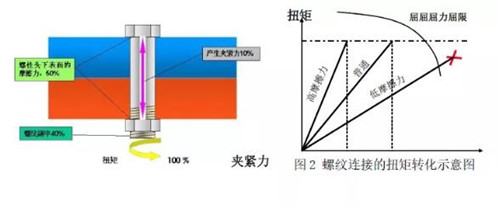

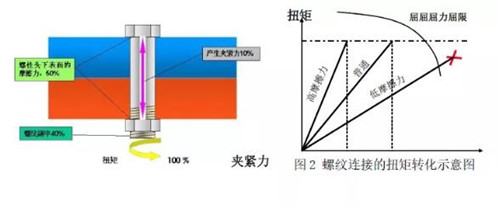

根据扭矩和收紧技术的原理,图2中显示了扭矩,摩擦和夹紧力之间的关系。当拧紧螺栓时,它会在连接器上产生夹紧力。但是,在组装过程中,摩擦的90%扭矩被消耗掉,只有10%的扭矩转化为夹紧力。但是在实际的组装过程中,无法测量夹紧力,很难检测到,我们可以测量扭矩。

1.摩擦的影响

通过计算:摩擦力的变化将导致连接器中夹紧力的40%变化。通过对扭矩控制方法的分析,螺栓的轴向拧紧力F与拧紧期间施加的扭矩T成正比。由t = kf表示,k是扭矩系数,其值主要取决于接触表面和螺纹齿之间的摩擦力。通常,K值约为0.2-0.4,有时在0.1和0.5之间。因此,抗摩擦力的变化对扭矩有很大影响。也就是说,当两个具有不同摩擦电阻的连接器以相同的固定扭矩值拧紧时,获得的螺栓扭矩大大不同,最多可达两次。在不同的螺母状态下,摩擦力是不同的,并且扭矩相应地变化。

2.连接模式

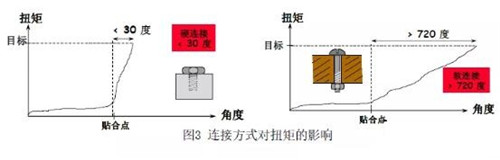

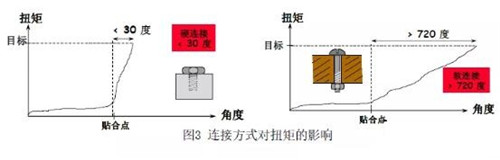

连接模式分为硬连接,中性连接和软连接。根据QC / T518-2007汽车螺纹紧固件收紧扭矩规格要求,8.8 m14×1.5级螺栓的扭矩为146N。M〜206n。M.静电扭矩为156n。M〜248n。M用于硬连接,141n。M〜247n。M用于中性连接和108N。M〜262n。M用于软连接。 The influence torque is ± 27.2%. In the process of tightening, the greater the deformation of the connector and the connected part in the axial direction of the bolt, the more "soft" the connection is; on the contrary, the more "hard" the tightening angle of the hard connection is less than 30 ° and the tightening angle of the soft connection is greater than 720 ° in the actual bending, but most of the connections are neutral connections, and the tightening angle is between 30 ° and 720 °. The influence of connection mode on torque is shown in Fig. 3

3、扭矩控制

1.正确评估静态扭矩值是收集100个实际扭矩测量值,然后在统计分析方法的帮助下计算标准偏差。根据实际的组装情况,±2S或±3S被视为控制范围的上和下弯曲极限,用于检查和评估螺栓连接的拧紧效果,并且测量的静态扭矩值必须在设置上下弯曲极限。但是,在制定静态扭矩值的过程中,由于人员和时间的限制,每个固定螺栓不可能100次测量。为了获得正确,快速,方便地配制静态扭矩值,可以使用以下经验公式(图中的t:中间值; t:图中的中间值; t:);

答:计算静态检查中间值SO和静态公差B,并根据公差变化的要求确定静态扭矩值≤35%≤35%,中位数变化≤15%,在一般的全球静态扭矩规范发布和更新过程中(NOA编号GGAS-345)。

2.在表3所示的控制范围和检查实际生产的控制范围和检查的动态扭矩和静态扭矩的比较表中。

3.制定静态扭矩测试规范。

4。结论

叶弹簧骑行螺栓的拧紧是汽车组件扭矩控制的关键点之一。合格的扭矩控制对组装质量非常重要,但是有许多影响扭矩的因素。在实际生产中,尤其是在大规模生产过程中,扭矩控制是一项复杂的工作。通过分析扭矩的影响,可以找到动态扭矩和静态扭矩之间的关系,并将其应用于公司进行实施质量控制QCO,解决螺栓拧紧扭矩控制方法的实际生产,提高产品质量的稳定性。